if you need a color that we do not stock in case quantities. We will be glad to special order it and give a 10% discount. Lead time is 4 to 6 weeks.

Industry norms allow polyester thread spool weights to vary by plus or minus 10% from the stated nominal weight. This means that you might slightly more or slightly less thread on any spool and use the term "nominal" weight in our descriptions. Here is a table that shows our nominal sizes and the weight ranges for each side including the weight of the spool itself. When a spool falls within these ranges we do not charge for overages or refund underages.

|

Nominal Weight |

Nominal Minimum |

Nominal Maximum |

Nominal Weight |

Nominal Minimum |

Nominal Maximum |

|

2 Oz |

2.6 Oz |

4.5 Oz |

8 Oz |

8.0 Oz |

10.5 Oz |

|

4 Oz |

4.6 Oz |

5.9 Oz |

12 Oz |

10.6 Oz |

15.5 Oz |

|

6 Oz |

6.0 Oz |

7.9 Oz |

16 Oz |

15.6 Oz |

19.9 Oz |

|

| The size of the spools used to hold the thread vary depending on the putup. Two and four ounce putups come on "king" spools that are 2.5 inches at the base and 4.0 inches high; sixteen ounce putups come on larger spools that are 4.5 inches at the base and 7.5 inches high.

These spool sizes meet industry standards and work well with most machines. The are some domestic (or home) sewing machines that use cartridge-like mini spools. In this case we have

Thread Cone Holders (right) that solve this problem by bypassing the machine's cartridge mechanism. |

|

|

|

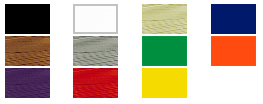

Color - We have polyester thread in over 100 colors. We make color selection easier by grouping colors into these broad color categories ( left ) - black, white, beige, blue, brown, gray, green, orange, purple, red and yellow. Then, we sequence shades, within each color category, from light to dark to make comparisons easier. |

|

Color accuracy is very important. We photograph each thread under controlled lighting conditions, minimize highlights and shadows by using small swatches, and visually match the color image on our site to the physical thread. This process results in a highly accurate color representation on our site. Unfortunately, we cannot promise an exact color match because:

- Monitor color settings and lighting around your monitor affects the color you see.

- Bonded thread on spools looks darker than the actual sewn thread. This is because sewing removes most of the bonding.

- Thread and fabric manufacturers have minor run-to-run color variations.

|

|

There are two things we can do to help you get a precise color match: We can send a reasonable number of samples so you can do the color matching; or you can send us a material swatch and have us do the matching. Please

contact us for help. |

|

Bonded or Soft?

- A bonded thread has a coating that reduces needle heat and fraying; a soft thread does not have this coating. Bonding only matters if you are using the thread for machine sewing. It makes no difference if you are hand sewing or using the thread to hang or reinforce things.

Bonding does little to help lightweight threads in sizes 46 or lower and soft threads work just as well. It is the norm for threads size 69 and higher. This is why almost all of our threads are bonded. |

|

Monocord - Regular polyester thread is made by twisting two or more plies together and bonding them. Monocord is made from hair-thin polyester filaments that are extruded together in a single ply. Up close, monocord thread is smooth, flat, and ribbon-like. Some say it looks like monofilament fishing line. Here are monocord's advantages and disadvantages: |

|

Advantages

- 10 to 14% stronger than twisted thread

-

Runs smoother, fewer needle changes

-

Works with both needles on a dual needle machine.

-

Excels at bi-directional sewing

-

Excels at low profile applications where stitches are buried in the material.

|

Disadvantages

-

Machines need to be re-tensioned when switching between twisted and monocord thread.

|

|

|

Bottom line, we do not recommend monocord thread for inexperienced, casual or low volume sewers because of re-tensioning. Monocord has significant advantages for commercial sewing such as upholstery, auto interiors, outdoor gear, and pet accessories. |

|

Elongation - This refers to a thread's stretchiness. Polyester thread has a 26% elongation factor. If you had a 100 foot length of polyester and pulled on it until it snaps, it would be 126 foot long at that point. This stretchiness is usually a good thing because most fabric and leather stretch. If polyester thread did not stretch with the material the it would either pucker (right) or snap.

Polyester can usually be used to sew inelastic materials like heavy vinyl and cardboard because the material's inelasticity holds the stitches in place. If elongation is a problem, consider

Kevlar thread,

spun polyester, or

string and cord. |

|

|

|

Twist - Almost all of our thread is left ("Z") twist because most machines designed for the U.S. market require left twist thread. Double-needle machines are the exception and require right twist ( or monocord ) for the left needle. We have a very limited selection of right twist polyester thread available for these customers. Thread twist does not matter for hand sewing, hanging, or reinforcing applications. |