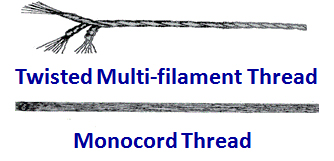

About Monocord Nylon and Polyester Thread

| ||||||||||

About Nylon Thread Sizes

-

Size 33 / Tex 30 / Govt. AA - Lightweight thread used it for sewing garments, thin leather purses and wallets. Use needle sizes 80/12 to 90/14

-

Size 46 / Tex 45 / Govt. B - Lightweight thread used for sewing lightweight tents, thin leather, outdoor garments, and delicate upholsteryUse needle sizes 90/14 to 100/16

-

Size 69 / Tex 70 / Govt. E - Our most popular size, with the widest color selection of all our sizes. It is a middleweight thread and the largest size most home sewing machines can handle. Typical uses include sewing lightweight furniture upholstery, leather, outdoor gear, garments, upholstery, drapes. Use needle sizes 100/16 to 110 /18

-

Size 92 / Tex 90 / Govt. F - Middleweight thread used for sewing upholstery, leather, auto interiors, military gear, dog collars, banners, and blankets. Usually requires a commercial machine. Use needle sizes 110/18 to 125/20

-

Size 138 / Tex 135 / Govt. FF - Middleweight thread whose stitches are noticeable. Use it for sewing upholstery, leather, auto interiors, tents, taupaulns, banners, musical instruments, covers, dog collars. Use needle sizes 125/20 to 140/22

-

Size 207 / Tex 210 / Govt. 3-Cord - Heavyweight thread whose stitches are very noticeable. Use it for sewing leather, upholstery, auto interiors, covers, and horse tack. Use needle sizes 140/22 to 180/24

-

Size 277 / Tex 270 / Govt. 4-Cord - Heavyweight thread whose stitches are highly visible. Use it for sewing saddles and tack, holsters, sheaths, belts, and heavy duty tarpaulins and covers. Requires a commercial or heavy duty machine. Use needle sizes 180/24 to 230/26

-

Size 346 / Tex 350 / Govt. 5-Cord - Heavyweight thread with stitching becoming a focal point. Used for sewing conveyor belts, heavy duty tarpaulins and covers, holsters, sheaths, belts, and shoe repair. Requires a heavy duty machine. Use needle sizes 230/26 to 260/28

-

Size 415 / Tex 410 / 6-Cord - Heavyweight whose stitches become the focal point. Use it for sewing boots and shoes, conveyor belts, heavy duty tarpaulins and covers, holsters, sheaths, belts, and hanging objects. Requires a heavy duty machine. Use needle sizes 280/28 to 330/30

-

Size 554 / Tex 600 / Govt. 8-Cord - Our heaviest nylon thread with about a 1 mm diameter. Its stitches become a focal point. Use it for sewing shoes and boots, conveyor belts, heavy duty tarpaulins and covers, holsters, sheaths, belts, and hanging objects. Use needle sizes 330/30 to 360/32